News

Why use APP 4?

Posted by Pam Bialiy on

The following article has been authored by John Heaney. Like the reciprocating cylinder (Apparatus 3), the flow-through diffusion cell (Apparatus 4) is quite rare compared to baskets (Apparatus 1) and paddles (Apparatus 2). But there are some distinct advantages to flow-through cell that can make it a boon to certain formulations. The design of the flow-through cell consists of a cell with specific dimensions with the dissolution media fed through it by a pump. The dissolution media is typically stored in a reservoir. The media can be recirculated which is referred to as a closed-system; or constantly dispensed and collected...

Immersion/Enhancer Cells vs Franz Cells

Posted by Pam Bialiy on

The following article has been authored by John Heaney. While Immersion/Enhancer Cells and Vertical Diffusion/Franz cells are both used to test semi-solid dosage forms; the capabilities of each apparatus are important to understand before deciding which is best for your lab. Testing of semi-solid dosage forms is broadly categorized into In-Vitro Permeation Testing (IVPT), and In-Vitro Release Testing (IVRT). The types of testing serve very different purposes and have different requirements. IVPT is primarily used to simulate how a semi-solid dosage form will behave in-vivo or when a patient makes use of it. This typically uses bio-relevant media and has...

Impact of Deaeration on Dissolution

Posted by Pam Bialiy on

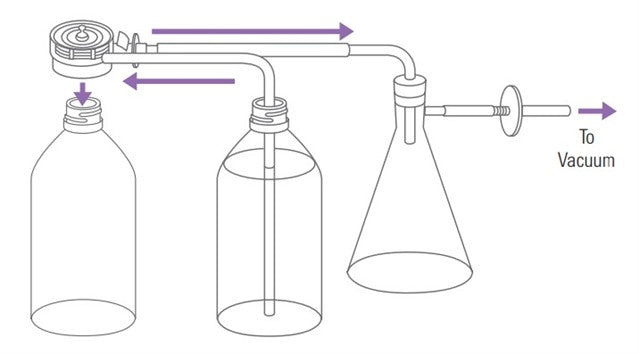

The following article has been authored by John Heaney. Deaeration, or degassing, of dissolution media is not required for every dissolution method, but when it is required it is critically important. The USP Prednisone PVT requires deaeration of the dissolution media and the tablet is formulated to show whether or not the deaeration method is adequate. Deaeration tends to have a larger impact on dissolution results as compared to other factors regarding the dissolution test. How this shows itself can change depending both on the apparatus, and the dosage being tested. How to deaerate is largely up to the...

APP 5 vs APP 6- which should I use?

Posted by Pam Bialiy on

The following article has been authored by John Heaney. Transdermal systems, or TDS, are often patches which when placed on the skin will deliver a drug over an extended period of time. Like any drug product, these need to be tested to ensure they are providing therapeutic benefit to the patients. In many cases, the best way to do this is performing a dissolution test using Apparatus 5, paddle over disk or watch glass, or Apparatus 6, the rotating cylinder. TDS are typically affixed to the apparatus using cellophane tape on the back (the part visible when the patch is...

Hydrodynamic Effects of Resident vs Manual Probes/Cannula

Posted by Pam Bialiy on

The following article has been authored by John Heaney. Does the presence of a resident sampling probe affect the hydrodynamics of a dissolution vessel? Yes, yes it does. The more important questions are how strong is the change in the hydrodynamics and is it strong enough to affect testing? USP <1092>, an advisory chapter addresses this directly with: Sampling probes may or may not remain in the vessel throughout the entire run. Sampling probes or fiber-optic probes can disturb the hydrodynamics of the vessel; therefore, adequate validation should be performed to ensure that the probes are not causing a significant...